Dung-gineering’ Breakthrough Turns Cow Manure into Everyday Materials

By Science Correspondent

Researchers from UCL and Edinburgh Napier University have developed a new method to turn cow dung into a valuable manufacturing material—cellulose—used in products ranging from surgical masks to food packaging.

The technique, described in The Journal of Cleaner Production, uses an innovation called ‘pressurised spinning’ to extract cellulose from manure, offering a cleaner, cheaper alternative to current manufacturing processes that often rely on toxic chemicals.

It’s the first time manufacturing-grade cellulose has been made from animal waste, showcasing a circular economy approach that turns waste into resource.

“Our initial question was whether it could be possible to extract the tiny fragments of cellulose present in cow manure, which is left over from the plants the animals have eaten, and fashion it into manufacturing-grade cellulose materials,” said senior author Professor Mohan Edirisinghe of UCL Mechanical Engineering.

“Extracting the fragments from dung was relatively straightforward using mild chemical reactions and homogenisation, which we then turned into a liquid solution. But when we tried to turn the fragments into fibres using pressurised spinning technology, it didn’t work,” he explained.

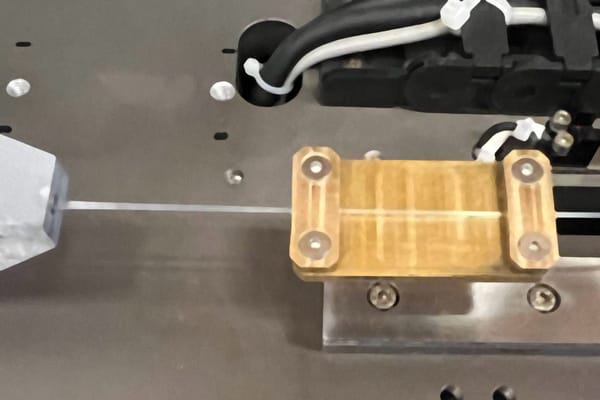

“By a process of trial and error, we figured out that using a horizontal rather than a vertical vessel containing surface nozzles and injecting the jet of liquid into still or flowing water caused cellulose fibres to form. We were then able to change the consistency of the liquid to create other forms, such as meshes, films and ribbons, each of which have different manufacturing applications.

“We’re still not quite sure why the process works, but the important thing is that it does. It will also be fairly easy to scale up using existing pressurised spinning technology, the vessels for which were designed and built in the UCL Mechanical Engineering workshop.”

The new method—called horizontal nozzle-pressurised spinning—is energy-efficient and doesn’t need the high voltages required in other fibre-making methods like electrospinning.

The team believes existing spinning machines can be adapted, though collecting and transporting manure may be the biggest challenge.

“Dairy farm waste such as cow manure is a threat to the environment and humans, especially through waterway pollution, the release of greenhouse gases into the atmosphere when it decomposes, and the spread of pathogens,” said Ms Yanqi Dai, first author from UCL Mechanical Engineering. “It is also often a burden on farmers to dispose of properly.

“Horizontal nozzle-pressurised spinning could be a huge boost to the global dairy farming industry, by putting this problematic waste product to good use and perhaps creating a new source of income.”

The researchers are now looking to partner with dairy farms to scale the process.

With animal waste expected to increase by 40% between 2003 and 2030, turning manure into materials could help both the planet and the farming industry.

Core research was supported by UK Research and Innovation (UKRI).

If you have a positive story or uplifting news to share, we’d love to hear from you!

Just email us at news@goodnewspost.co.uk.

Whether it's a local hero, an act of kindness, or a personal win, your story could help spread joy and improve someone’s mental health. Let’s make the world a little brighter, one good news story at a time.

And don’t forget—you can sign up for free to get the latest feel-good stories straight to your inbox!